MOLD MAKING

Equipment plays a key role in precision mold making, especially for hi-end mold, of which all cavities need to

be highly consistent. So we continuously invest in high precision machining equipments. Our tool room is

equipped with advanced high speed CNCs, sinker EDMs, Double Head EDM, WEDMs, grinders, etc.

Our dozens of tool-makers are experienced in DME Molds & Hasco Mold making, most of them have been

with us since the very beginning of the company establishment.

PRECISION COMPONENTS MACHINING

Our fully-equipped workshop can also undertake custom-machining works from customers. We make all kinds

of Precision Metal components including but not limited to Mold Components. All components are made from

best materials, using our advanced high speed CNCs, EDMs and Grinders, thus to guarantee high precision and

cosistence of parts.

QUALITY CONTROL

Quality is the essential factor from where customer’s satisfaction arises. To meet customer’s requirements, we

have established independent QC department equipped with advanced inspection devices to set up an adaptive

and cost-effective approach using the best processes for each step as following:

• Mold design control

• Mold steel hardness inspection

• Mold electrodes inspection

• Mold core and cavity steel dimension inspection

• Mold pre-assembly inspection

• T1 sample inspection

• Mold shipping inspection

INJECTION MOLDING

J D owns a in-house injectiom molding room, which equipped with advanced high precision molding machines like

HAITIAN ZHAFIR VENUS SERIES with clamping force ranging from 80 to 328 tons. In addtion to its ordinary use

for mold trials, most of the time it operates to provide contract molding services to our customers.

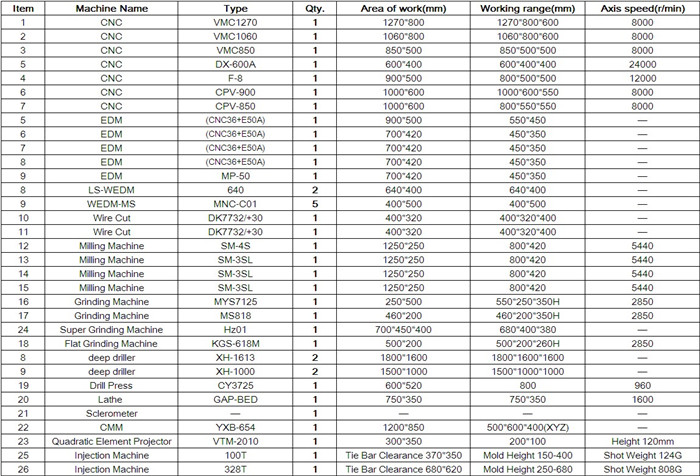

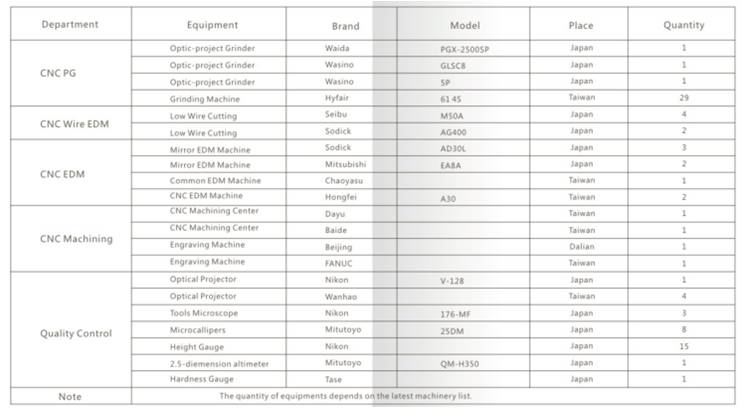

We list some of our advanced equipments as below,